According to the requirements of the Electrical Installation Rules, all newly constructed electrical wiring has an additional conductor. It is called a protective conductor (PE), marked with alternating stripes of yellow and green.

Protective conductors are connected to the housings of electrical appliances and connected to the ground loop. Household appliances: computers, washing machines, electric stoves, microwave ovens - connected to protective conductors through the grounding contacts of sockets.

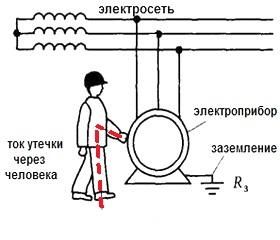

When the insulation of household appliances breaks down, their cases are energized. In case of contact with the case of a damaged device, a person will be shocked by an electric current. Intentional connection of cases to the ground during insulation breakdown leads to a short circuit, which will turn off the protection device, and the damaged equipment will be de-energized in a timely manner.

Even if the current is insignificant and no shutdown occurs, when a person touches the case, the current through his body will have a value that is not dangerous for his life. The human body has a resistance of tens to hundreds of thousands of ohms, and the resistance of grounding conductors does not exceed a few ohms. Therefore, the current through the human body will be much less than the current flowing into the ground through protective conductors.

In addition to protecting people, grounding instrument cases shields the electromagnetic fields emitted by them during operation. This reduces the level of interference that interferes with the operation of other devices.

Protective conductors must not be connected to the neutral bus of the electrical panel. Old electrical wiring is prone to breaks in the neutral conductor circuits, the result of which will inevitably be the appearance of some potential relative to the "ground" on the neutral wire. The value of the potential can reach up to 220V and, if it is on the body of the device, a serious injury awaits you.

It is forbidden to use gas pipes, heating and sewage pipes as protective conductors. Water pipes cannot be used for this purpose, since they are not always made of metal.

A ground loop is required to connect ground conductors.

The ground loop is a group of electrodes hammered into the ground and called vertical ground electrodes. Between themselves, they are connected by a horizontal ground electrode by means of welding. The horizontal earthing switch is brought to the wall of the building or goes directly to the input switchgear.

For the manufacture of vertical ground electrodes, steel corners or pipes are used, and horizontal ones - a steel strip or a round profile. They must not be painted, otherwise the electrical contact with the ground will be weak, and the circuit will lose efficiency.

If the building has structures buried in the ground, then they can also serve as a ground loop. They are called natural ground electrodes.

There is nothing complicated in making a ground loop, and you can do it yourself.

This will require:

1. A trench is dug with a depth of about 0.5 m and a width of 0.5-0.3 m. The length of the trench is about 5 m. The trench should be located so that its beginning coincides with the place near the wall of the building where the contour will go out.

2. After 1-1.5 m, ground electrodes are hammered into the trench with a sledgehammer. To facilitate the process, the ends of the ground electrodes must be sharpened with a grinder.

3. Grounding conductors are interconnected by a strip by welding. The end of the strip is displayed on the wall of the building or, if possible, is introduced into the building closer to the shield. A bolt is welded to the strip to connect the grounding conductor.

4. It is better to paint the joints in the trench, as the welds in the ground quickly collapse.

5. The strip outside and inside the building is painted with alternating stripes of yellow and green.

6. Before filling the trench, it would be nice to measure the resistance of the resulting circuit. This is done with special devices. If the resistance is insufficient, additional electrodes are clogged and the same strip is attached. And so on until the desired value is obtained (no more than 4 ohms).

If the devices are not available to you, use your own abilities and common sense when determining the number of electrodes. You need a lot of electrodes if the soil is sandy and even more if instead of soil there are solid stones. On chernozem, 5-7 electrodes are enough to obtain acceptable results. Do not sprinkle salt on the ground loop. Its conductivity will improve, but it will also rot faster.

7. We fill the trench with soil without construction debris.

8. An additional bus is installed in the shield - PE. It is connected by a yellow-green conductor to the ground loop terminal. Now it is possible to connect all electrical appliance enclosures to the PE bus.